PPT

|

SC

|

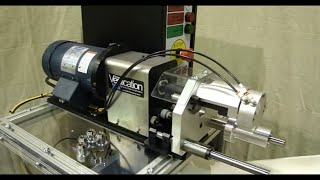

The PPT is an inexpensive push-pull machine for thread resizing, thread verifying, or remediation (chasing).

- All electric. Available in 220 vac or 120 vac. It’s portable.

- Supplied standard with New Vista 62020AC composite clutch and Type FP quick-change chuck.

- Will follow existing thread. It won’t crossthread (with the Squaring-up Plate).

- Tools will not jam in the threads (reverse-out is at higher torque than run-in).

- Will not tear up the mouth of the thread (won’t damage the thread at entry).

- No programming required at all.

- Tool Adapters available to run any gage or remediation tool and any shank configuration: taper shank, straight shank, all-threaded and Type BH.

- No operator training required.

- High torque on demand without operator effort.

- Variable speed settings: from 0 to 1,400 rpm.

- Slow-start feature is available with the basic unit.

- When used for thread verifying, cycles of 1 second are often attained (the operator’s part-handling time will be in addition to this).

- Complete changeover in seconds.

- Green light illuminates when correct thread depth has been achieved (with the Thread Depth Option).

- Can be run freehand, without any fixturing. But for fast cycles, order the Squaring-up Plate.

|

The SC is a fast machine for thread resizing, thread verifying, remediation (chasing) or retapping.

- Fast. Manually loaded floor-to-floor cycles of 3 to 4 seconds are regularly attained. Automated machines can be twice as fast.

- Models available that will run a large variety of internal or external, straight, or tapered threads.

- Utilizes production-proven, patented New Vista mechanisms and controls.

- Low maintenance and long thread tool life.

- Sensitive high-speed drive allows spindle to stop quickly if an obstruction is encountered.

- Will not subject the part or the tooling to damaging force or torque levels.

- Will not jam or stick in undersize or short threads.

- Outputs are available for integrated applications.

- Supplied tooled and proven out for your application.

- The economical way to run fast cycles in either high or low volumes.

- Will run a variety of parts.

- Available with Quick-change Toolholders and Fast-change Fixtures.

- Auto load, auto unload and auto sort options are available.

- Most changeovers in less than 30 seconds.

- Tooling available for hand-loaded or automated applications

|

For SC Machines

| FRAME SIZES |

THREAD SIZES: VERIFICATION |

THREAD SIZES: Remediation |

| MN-2 |

M3 – M10 (#4 – 3/8”) |

— |

| MN-4 |

M8 – M38 (5/16” – 1-1/2”) & Pipe threads through 1/2” |

M3 – M10 (#4 – 3/8”) |

| MN-5 |

M19 – M70 (3/4” – 2-3/4”) & Pipe threads through 2” |

M6 – M25 (1/4” – 1”) |

| MX-5 |

M32 – M90 (1-1/4” – 3-1/2”) |

M10 – M38 (3/8” – 1-1/2”) |

| MX-6 |

M70 – M190 (2-3/4” – 7-1/2”) |

_ |

A “–CMB” suffix is applied to the model number if the machine will be used for “Combination” thread gaging, or for pipe thread gaging.