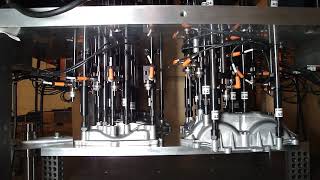

- Available as single-spindle Units, multiple-spindle Heads or complete Stations.

- Used to form, verify or remediate threaded holes (or external threads) by engaging appropriate thread tools with various threaded features.

- Will simultaneously form, verify or remediate threads of different sizes and pitches.

- Spindles are set individually for different torques and thread depths.

- Spindle Units can be equipped with compliant toolholders — to accommodate out-of-position holes.

- Not subject to damage from broken taps, missing or displaced holes, etc.

- Will not jam or stick in undersize or short threads. Won’t crossthread.

- Supplied proven out for your application.